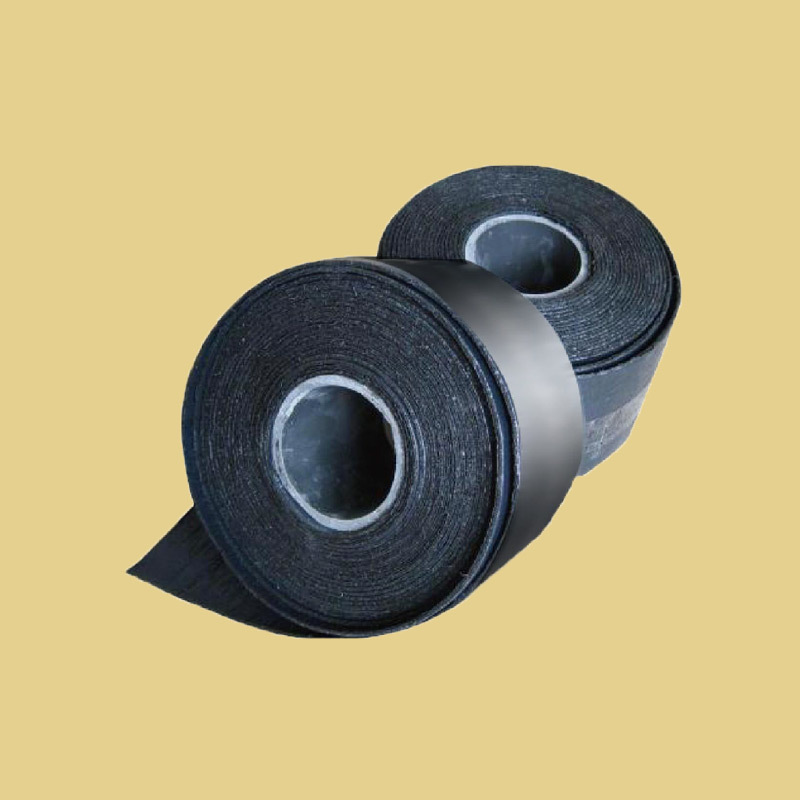

High density polyethylene HDPE/EVA waterproof board

Current Product Classification

- 产品描述

-

Product Presentatio

High density polyethylene (HDPE)/EVA waterproof board is a type of anti-seepage material made from polymer materials, which can prevent liquid leakage and gas evaporation. Widely used in construction, transportation, subways, tunnels, and engineering projects.

The main function of high-density polyethylene (HDPE)/EVA waterproof board is to prevent liquid leakage and gas volatilization. The role of high-density polyethylene (HDPE) (EVA) waterproof board in rock engineering is mainly to prevent seepage and isolation, but it also plays a role in strengthening and protecting. It is mainly used for anti-seepage in engineering projects such as earth and rock dams, rock fill dams, masonry dams, concrete dams, tailings dams, sewage storage dams, channels, and storage tanks, anti-seepage lining in subways, basements, and tunnels, anti-seepage in highway and railway foundations, and in conjunction with geotextiles such as long filament geotextiles and bentonite waterproof blankets in sanitary waste landfills.

Waterproof board HDPE waterproof board (new HDPE waterproof board) used for underground anti-corrosion and anti-seepage works is formulated based on ordinary waterproof board, selected high-quality low-pressure high-density polyethylene raw materials, scientifically proportioned carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizer and other auxiliary materials, and made by three-layer co extrusion technology with the most advanced fully automatic geotechnical production equipment in the world at present. This production line is highly automated, from order input, formulation, feeding, processing to quality monitoring, all of which are fully controlled by computers and operated strictly based on scientific data. And it can simultaneously use the latest raw materials (with super strong tensile strength), such as Metallurgy and traditional PE, EVA, LLDPE, etc. All products are produced according to the American ASTMD standard and meet or exceed national standards.

Product Features

1. Excellent flexibility, impermeability, elongation, and wear resistance;

2. Has good isolation and puncture resistance;

3. No chemical pollution;

4. Resistant to acid, alkali, and various chemical substances, with good dimensional stability, good adhesion, and easy construction.

Scope of Application

This product is mainly used for civil engineering needs such as anti-seepage, isolation, reinforcement, and crack prevention in tunnels, transportation, municipal engineering, landfills, and drainage ditches.

Scope of Use and Construction Methods

★ Mainly applicable to industrial and civil buildings, public buildings, etc.

★ Various permanent key roof waterproofing projects.

★ Hot welding system for coil material

The lap joint of the roll material is bonded and overlapped by hot air, and adjacent rolls are overlapped by hot welding to form a bonding layer higher than the strength of the roll material, forming a continuous sealed waterproof layer of the roll material as a whole. Hot welding is suitable for fixing various rolls and substrates.

★ Roll material mechanical fixed roof system

The roll roofing system is generally mechanically fixed. The coil is laid empty on the base layer (or fixed insulation board), and in the adjacent lower layer coil overlap area, it is fixed to the base layer with mechanical fastening screws and fixing washers. The overlap between the upper layer coil and the lower layer coil is welded by hot air welding, so that the coil is connected into a whole sealed waterproof layer. The outer edge of the joint is sealed tightly with sealant according to the engineering needs.

★ Key points for construction of mechanical fixed layer system

Base layer: The base layer for laying rolls should be solid, flat, clean, and dry. The deformation joint area should be sealed according to the design first, and a roll material should be attached as an additional layer.

Pre laying of rolls: Lay the rolls in predetermined positions, which should be flat and straight, without twisting or overlapping adjacent rolls.

Mechanical fixation of the lower layer coil in the overlapping area.

·Hot welding in the overlapping area, with adjacent coil overlap width generally 150mm (long edge). The upper coil covers the mechanical fasteners of the lower coil. Before and after welding the overlapping edge, the welding area should be cleaned, and then evenly welded with a manual welding gun (or automatic welding machine).

Additional waterproofing for typical details:

Typical details such as the internal and external corners on three sides, pipe edges, and roots are treated with non reinforced water injection substrate as an additional waterproof layer, which is welded with hot air welding to the main waterproof layer.

The vertical facade roll material is fixed mechanically with metal pressure strips. It is recommended to embed waterproof sealing material on the base layer before fixing, and then seal it with sealing paste.

Product Consulting

Copyright @ 2024 Xinbao Waterproof Material Co., LTD