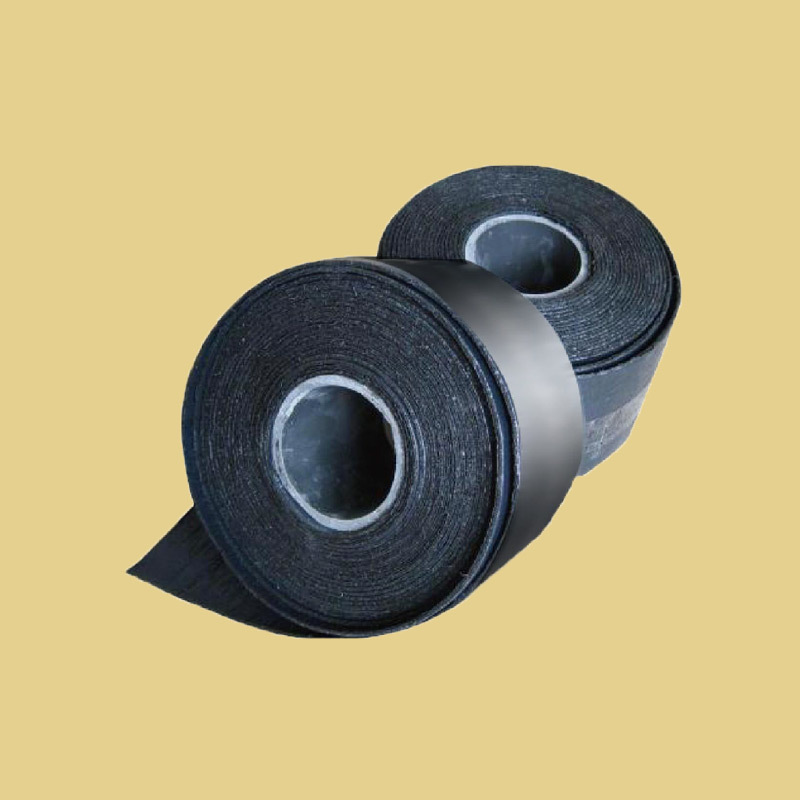

Chlorinated polyethylene (CPE) waterproofing membrane

Current Product Classification

- 产品描述

-

Product Features

CPE is a new type of high-end waterproof material. The main material of this product is made of special polymer synthetic material chlorinated polyethylene (CPE), added with appropriate amounts of chemical additives and fillers, and processed through processes such as plasticizing, mixing, and rolling with polyester non-woven fabric to form a polymer waterproofing membrane.

Scope of Application

Suitable for waterproofing projects with various requirements, used for anti-seepage and leakage prevention of roofs, basements, tunnels, caves, reservoirs, water pools, sewage treatment, drainage channels, floors, bathrooms, toilets and other projects. It can be used as the main waterproofing for various industrial and civil building roof walls, basements, swimming pool waterproofing projects.

Scope of Use and Construction Methods

1. The surface of the base layer must be flat, sturdy, and clean, with the internal and external corners made into circular arcs. Before construction, floating ash, floating slurry, and peeling layers must be removed, and the defective parts of the base layer must be repaired.

2. Additional layer construction. Special areas such as corners, pipe roots, and water outlets must have additional layers, and using our company's double-sided polyester tire chlorinated polyethylene waterproofing membrane for better results.

3. Preparation of cement-based special adhesive: Dissolve the chlorinated polyethylene waterproofing membrane cement-based special adhesive powder in water, add 40-50kg of water to 500g of adhesive powder per bag, stir evenly, and then mix directly with cement to form cement-based special adhesive (the adhesive concentration depends on the base surface, weather, and temperature conditions), ensuring no sedimentation, no clumping, and no segregation, and can be used.

4. Scrape cement-based adhesive: Apply cement-based adhesive evenly on the surface of the leveling layer. Before scraping the adhesive, the base layer should be moistened first. The degree of wetting depends on the base surface, weather, and temperature conditions, but there should be no large amount of water.

5. Apply rolls, exhaust air, and compact. When laying adhesive rolls, pay attention to promptly using a rubber scraper to remove air between the rolls and the base layer, and scrape off excess cement-based adhesive to fully bond them together.

6. Edge bonding of rolls: When laying and bonding rolls, use the prepared cement-based special adhesive as the bonding agent for edge bonding, while removing air and compacting. Ensure that the overlap width is not less than 80-100mm

7. Sealing at the edge of the coil: After the coil is glued, seal it with JS coating or polyurethane.

8. Comprehensive inspection. The finished rolls should be inspected in a carpet like manner, and any problems found should be repaired in a timely manner until they are qualified.

Product Consulting

Copyright @ 2024 Xinbao Waterproof Material Co., LTD